How does a chiller work?

To know how a chiller works, first we have to know about basic refrigeration cycle that is the core principle to basically 90% of all the cooling devices and machines in our world. No matter what kind of cooling or freezing apparatus you can think of, it is very likely it works using refrigeration cycle, only different in shape, size, appearance, and design purposes.

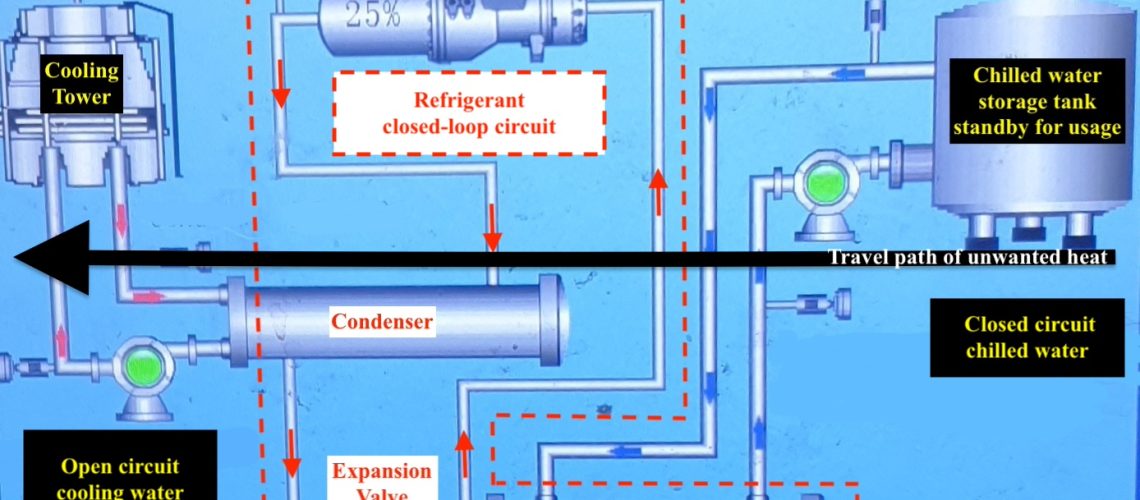

There are 4 main core components that make refrigeration cycle work are compressor, condenser, throttling device and evaporator. For chiller case, all these components are fitted together into a big metal frame and platform, with only 2 water piping connection ports on condenser (for water-cooled chiller only) and another 2 water piping connection ports on the evaporator.

What is Compressor?

A compressor in refrigeration cycle is used to compress and exert high pressure on refrigerant so that refrigerant is able to flow through the other 3 components to complete the cycle. In simple work, compressor is the power source to push the refrigerant and make sure if flows continuously.

What is Condenser?

It is a heat exchanger and the “Condenser” (or evaporator if the process going inside is evaporation) name suggests it is where the condensation takes place in which the vapour state refrigerant condensed into liquid state. Take it this way, after the compressor compress the refrigerant, the refrigerant will be heated as well and these excessive heat need to be removed out from the refrigerant. So, the heated refrigerant going into the condenser where the heat energy will move from hot refrigerant to much cooler ambient air(air-cooled chiller) or cooler water. As the refrigerant losing heat energy, it will change from vapour state to liquid state. To understand this phenomenon, try imagine about the steam trapped inside a cooking pot that will eventually become water droplets after cool down, and this is known as condensation.

What is Throttling Device / Capillary Tube (cap tube) / Thermal Expansion Valve (TXV) ?

Dun’t be scared by these technical names, it is actually a rather simple and easy to understand compare to other component in refrigeration cycle. Why do we say so? You can simply imagine it as just a device with smaller inlet hole and bigger outlet hole, or functioning like a expander expanding the diameter of the copper pipe, either mechanically or electronically. Technically speaking, it forces the refrigerant squeeze through a relatively much smaller hole before exiting to a larger copper piping (compared to inlet pipe size). This will cause the refrigerant experience a drastic drop in pressure, and hence the temperature will drop significantly as well.

We are not going to explain in detail here as it is way too difficult to be digested by general public, as for now we only need to take it as the fact that Pressure Drop causes Temperature Drop. If you need real-life illustration of this phenomenon, go get a pressurised spray paint and carry on a painting job. While the spray pressure is getting weaker and weaker, at the moment the spray is about used up, you will certainly feel the the spray can become cold within split second. This is same as what happen to the refrigerant when it flows through the throttling device, pressure drop and hence temperature drop.

What is Evaporator?

It is again the heat exchanger just with opposite purpose to the condenser. The refrigerant will evaporate inside this evaporator by absorbing heat from the relatively higher temperature chilled water. All the unwanted heat carried by the returning chilled water (from either machine or aircond) absorbed by refrigerant causing refrigerant evaporate and superheated before back to the compressor for next cycle. This is the core components where we get the “coolness” or chilled water we want.

Do take note that the refrigerant is permanently concealed in its closed loop and never mixed directly with the ambient air nor the water, except when leaking happens. Hence we should always monitor the condition chiller closely to detect and repair leaking at earliest possible time if there is any.

Summary

Now you have rough understanding on how a chiller creates chilled water or cool air to user utilising the principle of refrigeration cycle and welcome to the world of Thermodynamics!