A commercial kitchen exhaust system for restaurant and comprises of :

*optional

Correctly sizing the kitchen hood, fan and motor is essential for capture efficiency, comfort and safety. We size by duty class, hood length, canopy style, duct routing and accessories (filters/ESP), then select the fan at the required airflow and total static pressure with an engineering safety margin.

Indicative airflow per linear metre of hood (guide only; confirm on site):

Example (Malaysia heavy-duty wok line):

3.0 m canopy → target 7,000–9,000 m³/h. Duct ~12 m with 4 elbows → 350–500 Pa total static. Fan selected at the duty point with ~15% margin; motor typically 2.2–3.0 kW, depending on final routing.

Micro-CTA: Need help? We’ll size your hood, fan and motor based on drawings or a site visit.

Why it matters:

Exhaust without make-up air causes negative pressure, cross-drafts and poor capture. Evaporative make-up air provides large volumes of cooler supply air with low energy, improving staff comfort and hood performance.

Best-practice integration (bullets):

Benefits:

Micro-CTA: Design my make-up air plan (we’ll match airflow to your exhaust and layout).

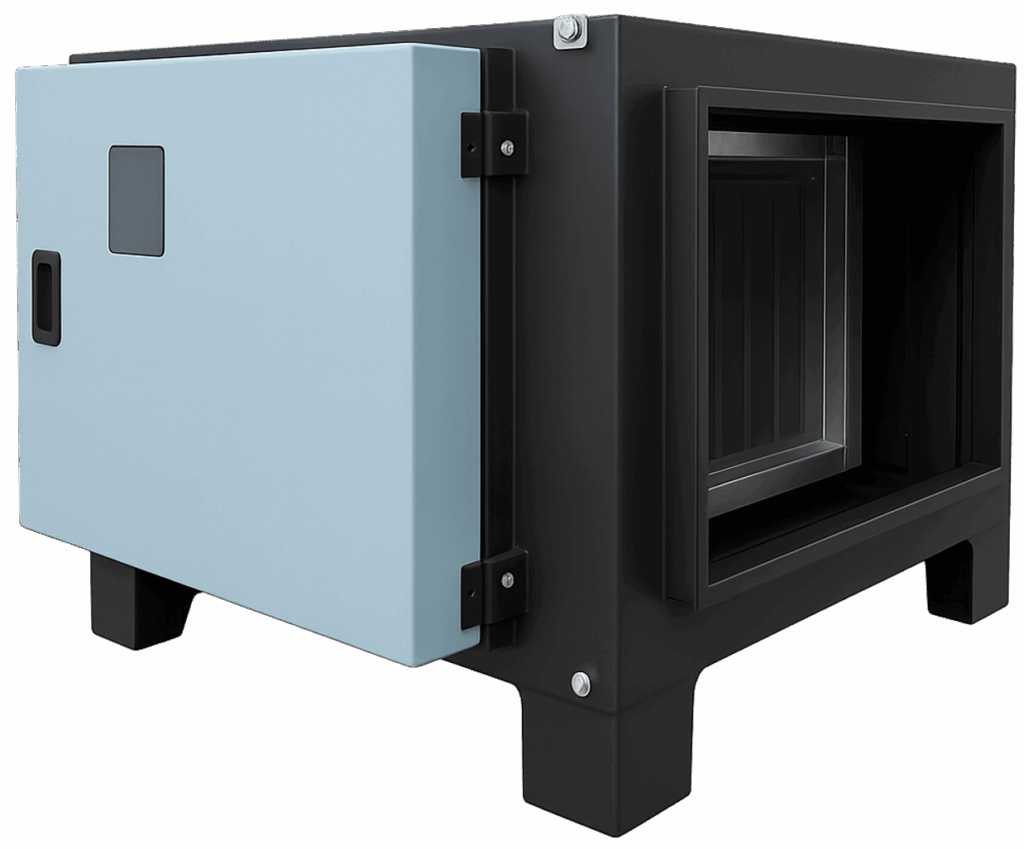

The electrostatic precipitator is the future of the kitchen exhaust hood system which effectively remove the oil mist/grease and release only clean air . This system is extremely useful when:

What it does:

ESP removes fine smoke and grease aerosols from the exhaust airstream, keeping ducts cleaner, reducing odour complaints and lowering fire risk—ideal for malls, dense urban sites and heavy cooking.

Benefits (bullets):

Placement (one-line):

Hood → Pre-Filter → ESP → Fan → Duct & Discharge (capture contaminants early, protect fan and duct).

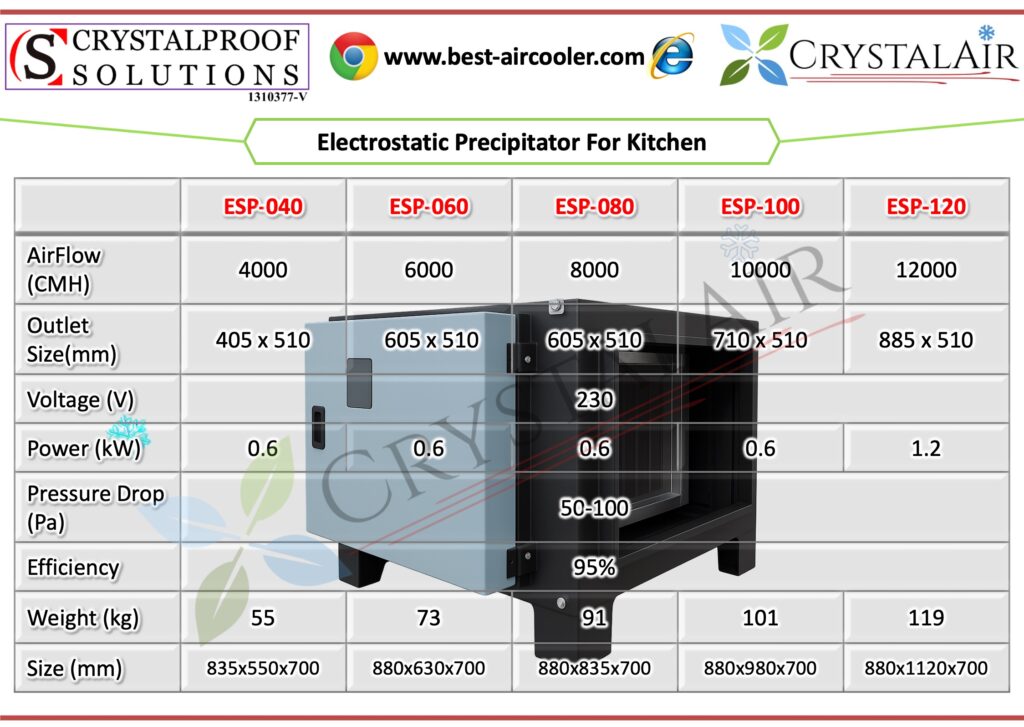

Typical ESP Specifications:

Maintenance note: cleaning interval depends on load (wok/charcoal lines need more frequent washing); include access doors and a wash bay or service workflow.

The primary purpose of an exhaust hood in a commercial kitchen is to remove smoke, heat, grease, and odors from the cooking area. It improves air quality, ensures a comfortable working environment, and reduces fire hazards by venting harmful contaminants outside.

A commercial kitchen exhaust hood should be cleaned regularly to prevent grease buildup, which can pose fire hazards. The frequency of cleaning depends on the volume of cooking, but generally, it should be done every three to six months.

There are several types of exhaust hoods, including canopy hoods, downdraft hoods, wall-mounted hoods, under-cabinet hoods, and island hoods. The choice depends on the kitchen layout and specific ventilation needs. When selecting an exhaust hood, consider the kitchen layout, cooking volume, and specific ventilation requirements. The size of the hood should extend beyond the cooking surface for optimal capture and ventilation.

The size of the exhaust hood depends on the size and type of cooking equipment used. A general rule is that the hood should extend 6 inches beyond the cooking surface on all sides for optimal ventilation.

An exhaust hood and a vent hood perform similar functions, but an exhaust hood is typically used in commercial settings and is designed to handle larger volumes of smoke, grease, and heat, while a vent hood is more common in residential kitchens.