Industrial chillers are critical for maintaining optimal temperatures in various industrial processes. Whether it’s in food processing, plastics, pharmaceuticals, or manufacturing, a well-maintained chiller ensures efficient cooling, reduces downtime, and extends equipment lifespan. In this article, we’ll explore the importance of industrial chiller maintenance and best practices.

Why Industrial Chiller Maintenance Matters

Regular chiller maintenance is not just a preventive measure — it’s a cost-saving strategy. Here’s why it matters:

- Energy Efficiency: Dirty coils, clogged filters, or low refrigerant levels make chillers consume more energy.

- Reduced Downtime: Preventive maintenance helps identify issues before they become costly breakdowns.

- Extended Lifespan: Proper care can extend a chiller’s lifespan by several years.

- Product Quality: Inconsistent cooling can affect production quality, especially in temperature-sensitive industries.

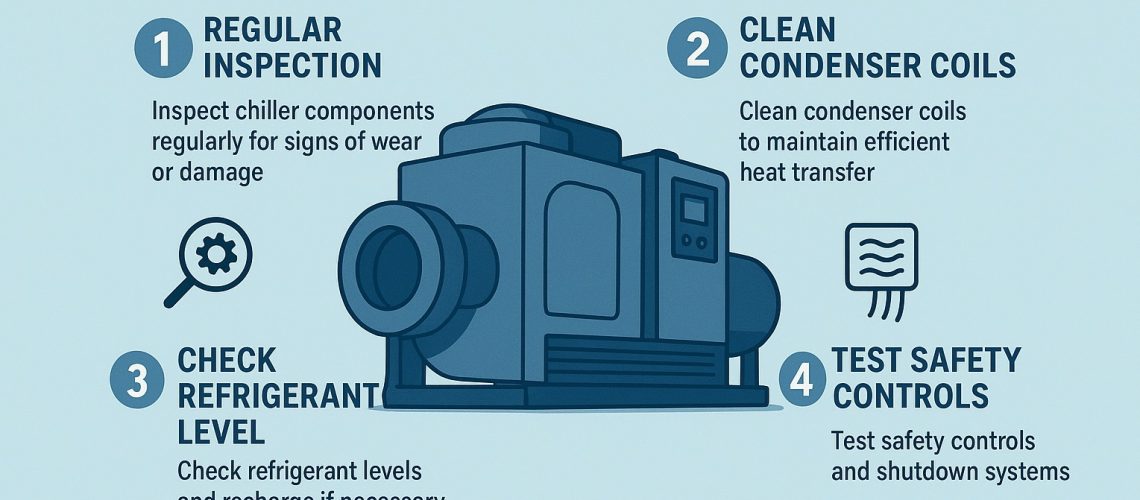

Key Maintenance Tasks for Industrial Chillers

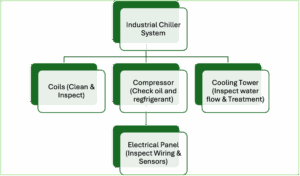

- Inspect and Clean Condenser & Evaporator Coils

- Dirty coils reduce heat transfer efficiency. Clean them regularly with chemical solutions or pressure washing.

- Check Refrigerant Levels

- Low refrigerant reduces cooling capacity and strains the compressor.

- Monitor Oil and Lubrication

- Ensure the compressor oil is clean and within recommended levels.

- Test Electrical Components

- Inspect wiring, fuses, contactors, and sensors for wear or damage.

- Check for Leaks

- Inspect pipes, valves, and joints for refrigerant or water leaks.

- Water Treatment

- Prevent scale, corrosion, and biological growth in water-cooled chillers by using proper water treatment systems.

- Monitor Operating Parameters

- Regularly track pressure, temperature, and flow rate to detect abnormalities early.

Maintenance Schedule for Industrial Chillers

- Daily: Monitor temperatures, pressures, and water flow.

- Weekly: Inspect refrigerant levels, check oil pressure, and listen for unusual noises.

- Monthly: Clean coils, inspect electrical panels, and test safety controls.

- Quarterly: Perform water treatment analysis and vibration checks.

- Annually: Conduct a full performance evaluation, replace worn parts, and recalibrate sensors.

Conclusion

Maintaining industrial chillers is essential for energy efficiency, cost savings, and uninterrupted production. By following a structured maintenance schedule, businesses can avoid expensive repairs and ensure smooth operations.

Consider scheduling annual professional servicing for detailed inspection and performance optimization.