Industrial chillers are vital for temperature control in manufacturing, food processing, pharmaceuticals, and other industries. When they malfunction, production can be disrupted, leading to costly downtime. To keep operations running smoothly, it’s essential to understand the common troubleshooting steps and repair guidelines for industrial chillers. However, a well-planned preventive maintenance plan for industrial chiller is mandatory as prevention is always better than cure.

Why Troubleshooting Industrial Chillers is Important

- Minimizes Downtime: Quick diagnosis prevents extended production halts.

- Reduces Repair Costs: Early detection of issues avoids expensive breakdowns.

- Ensures Efficiency: Timely troubleshooting maintains energy efficiency.

- Protects Equipment: Prevents secondary damage to compressors, pumps, or electrical components.

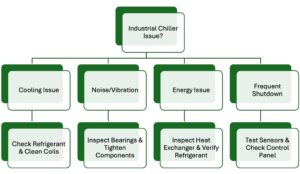

Industrial Chillers Common Problems How to Troubleshoot

1. Insufficient Cooling

- Possible Causes: Low refrigerant, dirty condenser coils, or blocked water flow.

- Troubleshooting:

- Check refrigerant levels.

- Inspect and clean condenser coils.

- Ensure adequate water flow in evaporator and condenser.

2. High Energy Consumption

- Possible Causes: Fouled heat exchanger, incorrect refrigerant charge, or aging components.

- Troubleshooting:

- Clean heat exchangers.

- Verify refrigerant charge.

- Inspect for worn-out compressor or pump parts.

3. Unusual Noise or Vibration

- Possible Causes: Loose parts, bearing failure, or cavitation in pumps.

- Troubleshooting:

- Tighten bolts and mounting hardware.

- Inspect bearings for wear.

- Check pump inlet pressure.

4. Frequent Cycling or Shutdowns

- Possible Causes: Faulty sensors, control panel errors, or electrical issues.

- Troubleshooting:

- Test temperature and pressure sensors.

- Inspect control wiring.

- Check safety shutdown settings.

5. Leaks (Water or Refrigerant)

- Possible Causes: Damaged piping, valve failures, or gasket deterioration.

- Troubleshooting:

- Conduct leak tests with detectors.

- Tighten or replace seals.

- Repair or replace faulty piping.

Industrial Chillers – Repair Guidelines

- Always Isolate Power Supply before inspection or repair.

- Follow Manufacturer’s Recommendations for replacement parts and repair techniques.

- Replace Faulty Sensors and Electrical Components promptly to avoid false alarms.

- Use OEM Spare Parts to ensure system compatibility and performance.

- Schedule Professional Servicing annually for in-depth inspection and performance testing.

Conclusion

Industrial chiller troubleshooting and repairs are critical to maintaining energy efficiency, equipment longevity, and uninterrupted production. By addressing issues early and following a structured troubleshooting process, businesses can save money and reduce downtime.