Industrial water chillers are the backbone of many facilities in Malaysia, from factories to hospitals. But when a chiller fails, it can lead to costly downtime, product spoilage, or uncomfortable working conditions. The good news? Most chiller problems can be anticipated—and prevented—with proper industrial chiller maintenance guide.

In this article, we’ll cover the top 5 most common industrial water chiller problems facility managers face, and how to avoid them

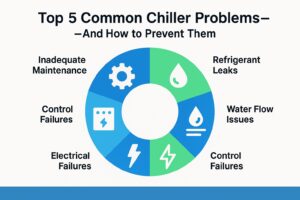

Common Chiller Problems 1 – Insufficient Cooling Capacity

The problem:

Your chiller runs, but the temperature never reaches the desired set point. This often happens due to fouled condenser tubes, clogged filters, or low refrigerant charge.

How to prevent it:

- Schedule tube cleaning and descaling at least once a year.

- Replace or clean filters regularly.

- Monitor refrigerant levels through preventive maintenance.

Common Chiller Problems 2 – High Energy Consumption

The problem:

Chillers are one of the largest energy consumers in a facility. When efficiency drops, electricity bills rise. Causes include dirty heat exchangers, worn compressor parts, or poor water treatment.

How to prevent it:

- Implement regular energy audits.

- Ensure proper water treatment to avoid scaling and fouling.

- Upgrade controls and install variable frequency drives (VFDs) where possible.

Common Chiller Problems 3 – Water Leaks and Poor Water Quality

The problem:

Leaks in chilled water or condenser water piping not only waste resources but also cause corrosion and reduce system reliability. Untreated water can also create scale, rust, or microbial growth inside pipes.

How to prevent it:

- Conduct routine leak inspections.

- Invest in a professional water treatment and chemistry program.

- Use corrosion inhibitors and monitor water pH.

Common Chiller Problems 4 – Compressor Failures

The problem:

The compressor is the heart of the chiller. Failures can be triggered by lubrication issues, electrical faults, or short cycling. Repairs are often expensive and time-consuming.

How to prevent it:

- Track oil quality and replace it according to OEM recommendations.

- Inspect motor windings and starter components.

- Install monitoring devices to detect abnormal vibrations or electrical loads.

Common Chiller Problems 5 – Control System Malfunctions

The problem:

Modern chillers rely on electronic controls and sensors. Faulty sensors, miscalibrated setpoints, or outdated controllers can cause inefficiency—or full system shutdown.

How to prevent it:

- Keep control panels clean and dry.

- Regularly test and calibrate sensors.

- Upgrade outdated control systems to modern BAS-compatible units.

Pro Tip: Preventive Maintenance Saves More Than It Costs

Many facilities in Malaysia only service chillers when problems arise. But a preventive maintenance contract with a trusted partner reduces downtime, increases efficiency, and extends equipment life.

Good practices are advised:

- Quarterly preventive maintenance inspections

- Annual full system health checks

- Professional water treatment monitoring

Conclusion

Chillers are critical assets for industrial and commercial operations. By addressing the five most common problems—cooling capacity issues, high energy use, water leaks, compressor failures, and control malfunctions—you can protect your investment and ensure uninterrupted operations.

If you want peace of mind for your facility, talk to CrystalAir—Your Ventilation Expert. Our experienced team provides design, engineering, maintenance, rental, and water treatment services tailored to Malaysian businesses.