A complete technical resource for facility managers managing industrial water-cooled chiller systems in Malaysia.

This page serves as a central knowledge hub, guiding facility managers through:

Each section below links to in-depth technical guides for deeper understanding.

*For service support, visit our Industrial Chiller page

This guide is designed to support technical decisions with real operational insight.

A structured maintenance program helps to:

Chiller alarms are protective mechanisms—not faults to ignore.

Understanding alarm causes allows facility teams to respond correctly and avoid repeated trips.

Common alarms include:

*Stay tuned! Detailed guide coming soon in April 2026

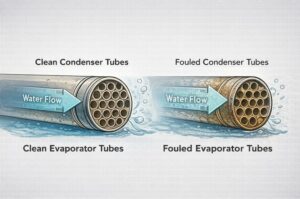

Evaporator and condenser fouling is a leading cause of:

Even minor fouling significantly reduces heat transfer efficiency.

Proper water treatment is essential to prevent:

*Stay tuned! Detailed guide coming soon in March 2026

Industry standards from ASHRAE consistently highlight water quality as a core reliability factor for water-cooled chillers.

Understanding compressor design helps facility managers make better decisions when faults, efficiency loss, or upgrades occur.

Key compressor types:

Each has different:

*Stay tuned! Detailed guide coming soon in February 2026

A professional chiller overhaul can extend equipment life by 8–12 years when performed at the right time.

Typical overhaul scope includes:

*Stay tuned! Detailed guide coming soon in February 2026

Replacing a chiller is a major capital decision.

In many cases, overhaul or optimisation delivers better ROI.

Key decision factors:

Many chillers still have recoverable efficiency, even after years of operation.

Optimisation may include:

Chiller lifespan is not fixed—it is managed.

Facilities that:

…routinely operate chillers 10–15 years longer than those relying on reactive maintenance.

*Stay tuned! Detailed guide coming soon in April 2026

If your facility is experiencing:

A professional inspection can identify:

If you need engineering guidance for your chiller system, speak with our team.