A commercial kitchen exhaust system is not just an exhaust hood. It is a complete ventilation solution that includes the exhaust hood, ducting, exhaust fan, air balancing, and make-up air design — all working together to remove contaminants efficiently while maintaining safe and comfortable kitchen conditions.

This complete guide explains how commercial kitchen exhaust and ventilation systems work, the different system components involved, and the key design considerations for kitchens operating in Malaysia’s hot and humid climate. Whether you are planning a new kitchen, upgrading an existing system, or solving persistent heat and smoke problems, this guide will help you understand what matters before installation. Click on the title of each topic to read more!

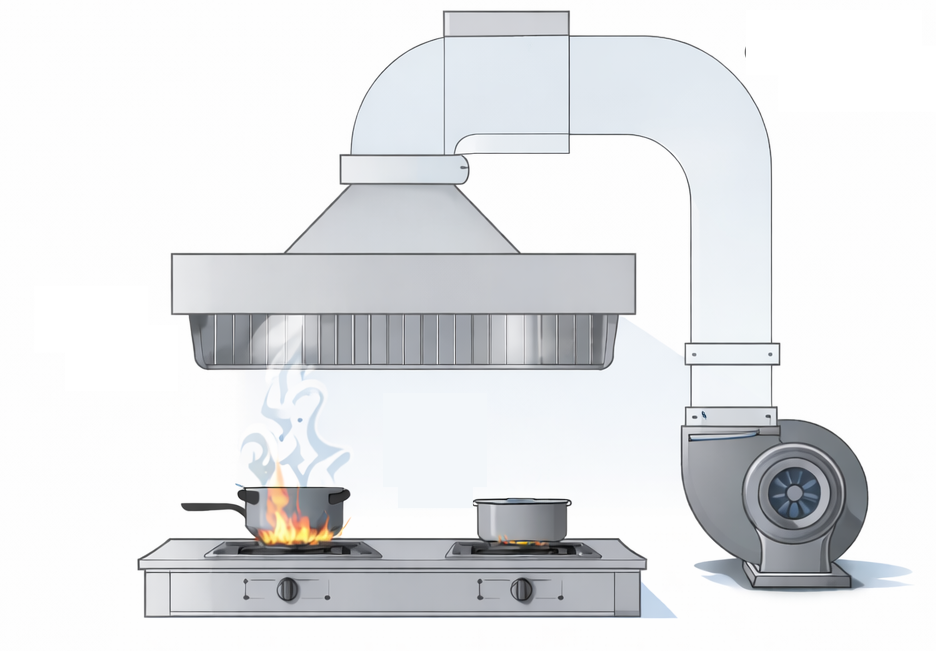

A commercial kitchen exhaust system functions by capturing, conveying, and removing contaminated air generated during cooking. This includes heat, grease-laden vapour, smoke, and odour.

The process begins at the exhaust hood, which is designed to capture rising hot air and contaminants at the source. The captured air is then transported through ducting, driven by an exhaust fan, and safely discharged away from the building.

For the system to work efficiently, exhaust air removal must be balanced with make-up air supply. Without adequate make-up air, the kitchen can experience negative pressure, leading to poor hood capture, excessive heat, and air being drawn in from undesirable areas such as toilets or back-of-house spaces.

A well-designed system treats the kitchen as an integrated airflow environment, not a collection of separate components.

Different cooking operations require different hood designs. Selecting the correct hood type is essential for effective smoke capture and compliance.

Common commercial kitchen exhaust hood types include:

Wall-mounted canopy hoods

Installed against a wall, suitable for most standard commercial cooking lines.

Island canopy hoods

Suspended from the ceiling, used where cooking equipment is located away from walls.

Low-profile or compact hoods

Designed for kitchens with limited ceiling height.

Light-duty vs heavy-duty hoods

Heavy-duty cooking (e.g. wok, charbroiling, deep frying) requires higher capture velocities and stronger airflow than light-duty applications.

Choosing the wrong hood type often results in smoke escaping into the kitchen, even when the exhaust fan is running.

Airflow sizing is one of the most critical design steps in any kitchen exhaust system.

An undersized exhaust fan will fail to remove heat and smoke effectively, while an oversized fan can create excessive negative pressure, noise, and energy waste. Proper sizing must consider:

Type and intensity of cooking

Hood size and configuration

Duct length and number of bends

System static pressure losses

Fan selection should never be based on rule-of-thumb alone. Accurate airflow calculation and pressure assessment ensure the system performs as intended under real operating conditions.

Ducting plays a major role in system efficiency, safety, and long-term maintenance.

Best practices for commercial kitchen exhaust ducting include:

Keeping duct runs as short and straight as possible

Minimising sharp bends and unnecessary elbows

Using appropriate duct thickness for grease exhaust

Providing access doors for regular inspection and cleaning

Poor ducting design increases grease accumulation, raises fire risk, and makes maintenance difficult and costly. Even a powerful exhaust fan cannot compensate for badly designed ductwork.

One of the most common problems in commercial kitchens is excessive heat build-up, even when exhaust systems are running continuously.

This typically occurs when exhaust air is not properly replaced with make-up air. As hot air is removed, fresh air must be supplied to maintain pressure balance and ensure effective hood capture.

In Malaysia’s climate, make-up air strategies may include:

Dedicated supply ducts positioned near the hood

Diffused air delivery to avoid drafts

Evaporative cooling solutions for energy-efficient heat reduction

A balanced exhaust and make-up air system significantly improves kitchen comfort, reduces staff fatigue, and enhances overall system performance.

Commercial kitchen exhaust systems play a crucial role in fire prevention and odour control.

Grease-laden vapour accumulates over time on hood filters, duct walls, and fans. Without proper design and maintenance, this grease becomes a serious fire hazard. Effective systems focus on:

Efficient grease capture at the hood level

Smooth duct interiors to reduce grease adherence

Easy access for regular cleaning

Proper airflow to prevent grease condensation

Odour control is also essential, especially for kitchens operating in shopping malls, mixed-use buildings, or residential areas. Poor exhaust performance often leads to persistent complaints and operational disruptions.

Many kitchens experience ventilation problems not because of faulty equipment, but due to design shortcomings.

Common issues include:

Kitchen remains hot despite exhaust system running

Smoke spills out from the hood during peak cooking

Grease dripping from hood or duct joints

Excessive system noise

Complaints from neighbouring tenants

In most cases, these problems are solved by reviewing airflow balance, ducting layout, hood selection, and make-up air strategy — rather than simply increasing fan size.

Selecting the right commercial kitchen ventilation system requires understanding more than just equipment specifications.

Key considerations include:

Type of cuisine and cooking methods

Operating hours and peak load

Kitchen layout and ceiling height

Local climate conditions

Maintenance access and long-term operating cost

A well-designed system prioritises performance, safety, and sustainability, rather than just initial installation cost.

Malaysia’s hot and humid environment places additional demands on commercial kitchen ventilation systems. High ambient temperatures, long operating hours, and dense urban locations make proper design especially important.

Local kitchens must account for:

Heat management without excessive energy consumption

Effective grease control in high-humidity conditions

Practical compliance with fire safety and hygiene expectations

Long-term reliability and ease of maintenance

A properly engineered system not only improves working conditions but also protects equipment investment and business continuity.

Most commercial cooking operations generate heat, smoke, or grease and require an exhaust hood to maintain safe and hygienic conditions.

Cleaning frequency depends on cooking type and usage, but regular inspection and scheduled cleaning are essential to reduce fire risk.

This is often caused by insufficient make-up air or poor airflow balance rather than lack of exhaust capacity.

While requirements vary, make-up air is strongly recommended for proper system performance and comfort.

Costs vary depending on kitchen size, cooking type, ducting complexity, and system design. It can be start from Rm7k for small kitchen.