Compressor is the main component for all the refrigerating system, especially for industrial chillers. At the heart of every chiller lies the compressor, responsible for circulating refrigerant and maintaining the cooling cycle. Choosing the right compressor type directly affects energy efficiency, reliability, and long-term performance. In this article, we’ll explore the main types of compressors used in industrial chillers, their advantages, and best applications.

Why the Compressor is Important in Industrial Chillers

The compressor acts as the engine of the chiller system, performing these critical functions: – Compresses low-pressure refrigerant gas into high-pressure gas. – Circulates refrigerant throughout the system. – Ensures consistent cooling efficiency. – Affects energy consumption and operating costs.

Compressor for Industrial Chillers

1. Reciprocating Compressors

- How it Works: Uses pistons and cylinders to compress refrigerant.

- Advantages:

- Cost-effective.

- Easy to maintain.

- Suitable for small to medium cooling loads.

- Best For: Small manufacturing facilities, HVAC systems, and lower-capacity chillers.

2. Scroll Compressors

- How it Works: Uses two interleaving spiral scrolls, where one remains fixed and the other orbits to compress refrigerant.

- Advantages:

- Quiet operation.

- High efficiency.

- Low maintenance.

- Best For: Commercial chillers, light industrial applications, and office buildings.

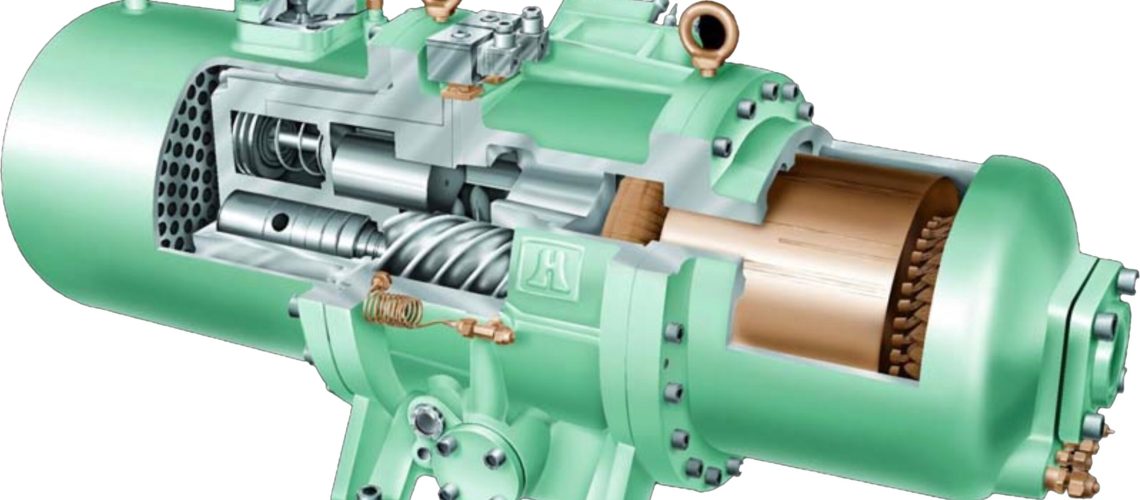

3. Screw Compressors

- How it Works: Uses two helical rotors (male and female screws) that mesh together to compress refrigerant.

- Advantages:

- High efficiency at partial loads.

- Long lifespan.

- Suitable for continuous operation.

- Best For: Large manufacturing plants, process cooling, and mid-to-high capacity chillers.

4. Centrifugal Compressors

- How it Works: Uses an impeller (like a turbocharger) to accelerate refrigerant and convert velocity into pressure.

- Advantages:

- Extremely efficient at large cooling capacities.

- Compact design for high-tonnage systems.

- Reliable for continuous heavy-duty operation.

- Best For: District cooling, large industrial plants, airports, and data centers.

Choosing the Right Compressor

The right compressor depends on: – Cooling Load Requirements: Small vs. large capacity. – Operating Conditions: Continuous vs. intermittent use. – Budget and Energy Efficiency: Initial cost vs. long-term savings.

Conclusion

Understanding the different types of compressors in industrial chillers helps businesses select the most efficient and reliable solution for their cooling needs. From cost-effective reciprocating units to high-capacity centrifugal compressors, the right choice ensures optimized performance, energy savings, and durability.

Always consult with a chiller specialist before upgrading or selecting a compressor type for your facility.