Superheat in Industrial Chiller – Definition

Superheat in Industrial chiller systems refers to the temperature of a vapor refrigerant above its saturation temperature (boiling point) at a given pressure.

- Saturation temperature = the temperature at which a refrigerant boils/condenses at a specific pressure.

- Once all liquid refrigerant has boiled off, any additional heat added to the vapor increases its temperature (not pressure) — this is called superheating.

Formula:

Superheat = Measured suction line temperature − Saturation temperature (from pressure)

Example:

- Suction line pressure corresponds to 4°C saturation temperature.

- Actual suction line temperature = 10°C.

- Superheat = 6°C.

Where It Happens?

- Evaporator outlet: After the refrigerant has absorbed heat and completely evaporated, it may continue to absorb more heat, raising its temperature above boiling point.

- Suction line (leading to compressor): This superheated vapor travels back to the compressor.

So when technicians measure superheat, they usually check it at the evaporator outlet or at the compressor suction line.

Superheat in Industrial Chiller Important?

Superheat is crucial because it ensures the compressor only handles vapor, not liquid. Compressors are designed to compress gas only — if liquid enters (a condition called liquid slugging), it can severely damage the compressor.

Benefits of controlled superheat:

- Protects the compressor (no liquid floodback).

- Shows evaporator performance — low superheat may mean overfeeding (too much refrigerant), high superheat may mean underfeeding or poor heat transfer.

- Helps optimize efficiency — proper superheat means the evaporator is fully used for boiling refrigerant and cooling air/product.

Typical Superheat Ranges

- Residential A/C systems (TXV controlled): 8–12°F superheat at evaporator outlet.

- Fixed orifice systems (piston/capillary tube): 10–20°F at compressor suction.

- Commercial refrigeration: often 4–8°F (closer control for efficiency).

(Values depend on system design and load conditions.)

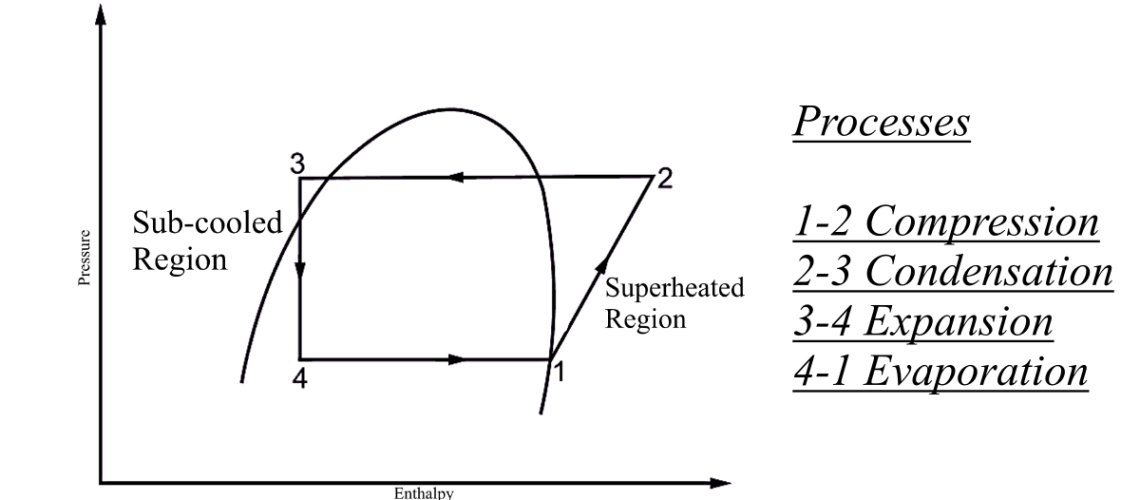

Superheat vs Subcooling

- Superheat: Extra heat added to vapor above its boiling point (protects compressor).

- Subcooling: Extra cooling below the condensing temperature in liquid state (ensures only liquid enters expansion device).

Both are key in refrigeration diagnostics.

Superheat In Diagnosing Problems

Superheat readings help troubleshoot system issues:

- Low/Zero → expansion valve overfeeding, or liquid floodback risk.

- High → underfeeding (restricted metering device, low refrigerant charge, dirty filter/drier, iced coil).

- Correct → system is balanced and efficient.

Summary:

Superheat is the amount of heat added to refrigerant vapor after it has fully evaporated in the evaporator. It is measured by comparing the actual suction line temperature to the refrigerant’s saturation temperature at suction pressure. Proper superheat is critical for compressor protection, system efficiency, and diagnostic purposes in refrigeration systems.