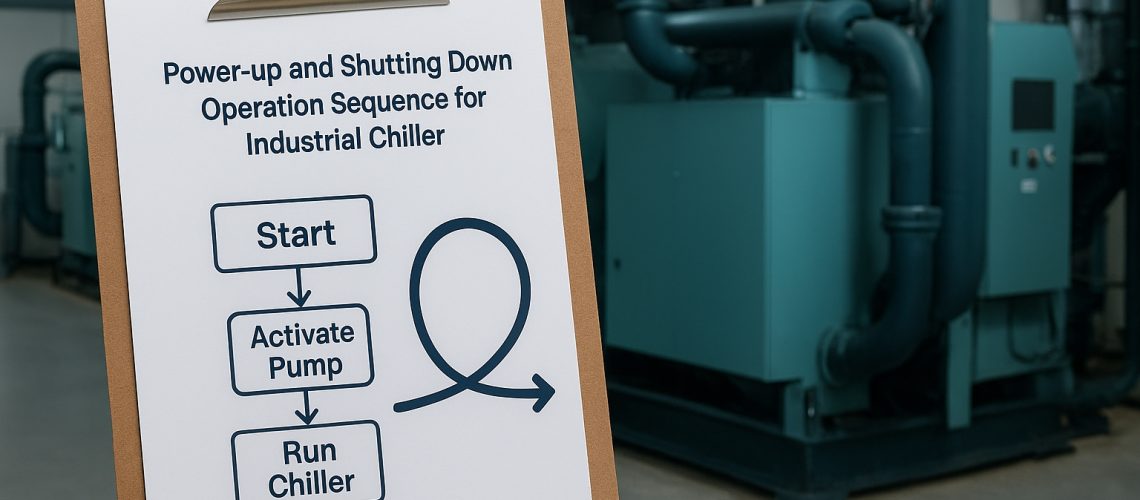

Industrial Chiller Operation Sequence

Industrial Chiller Operation Sequence is of top critical for maintaining efficiency, equipment life, and safety. In this blog, we’ll explore the step-by-step sequence for both operations, along with best practices, an infographic guide, and a professional featured image.

Why it matters?

Incorrect startup or shutdown of industrial chillers can cause: – High inrush current damaging electrical components – Excessive compressor wear – Refrigerant migration issues – Reduced system efficiency

Following the correct sequence ensures safe, efficient, and reliable operation.

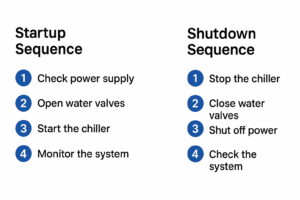

Industrial Chiller Operation Sequence : Start-up

Here is a typical startup sequence:

- Pre-Startup Inspection

- Check water supply, pumps, and flow rates.

- Verify electrical connections and voltage supply.

- Ensure valves are in the correct position.

- Cooling Tower & Pumps Start

- Start condenser water pumps.

- Start chilled water pumps.

- Start cooling tower fans (if applicable).

- Control Panel Initialization

- Power up the chiller control system.

- Confirm system readiness via control indicators.

- Compressor Start

- Engage compressors gradually.

- Monitor suction and discharge pressures.

- Load Adjustment

- Slowly introduce load to prevent thermal shock.

- Confirm stable chilled water outlet temperature.

Industrial Chiller Operation Sequence : Shut down

Here is a typical shut down sequence:

- Gradual Load Reduction

- Reduce chiller load step by step.

- Avoid sudden shutdown under full load.

- Compressor Shutdown

- Turn off compressors after the load is removed.

- Allow for oil return cycle.

- Pump and Tower Shutdown

- Shut off chilled water pumps.

- Shut off condenser water pumps.

- Turn off cooling tower fans.

- Control Panel & Safety Checks

- Power down the control panel.

- Record operational data for maintenance logs.

Best Practices for Operation

- Always follow OEM guidelines for your specific chiller model.

- Train staff to perform proper pre-startup inspections.

- Implement automatic sequencing controls where possible.

- Keep maintenance logs for predictive maintenance.

Conclusion

Adhering to the correct Start-Up and shutdown sequence for industrial chillers ensures energy efficiency, equipment protection, and reliable operation. A disciplined operational and maintenance routine for industrial chiller not only extends the chiller’s lifespan but also reduces downtime and maintenance costs.