Economizers in Industrial Chillers – Definition

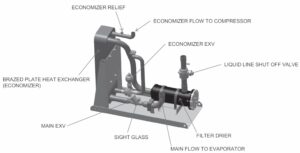

Economizers in industrial chillers is a specialized component integrated into a chiller system to improve efficiency by recovering and reusing energy. It allows a portion of the refrigerant to bypass the compressor, reducing its workload. By precooling the liquid refrigerant before it enters the evaporator, the economizer helps achieve lower energy consumption while maximizing cooling capacity.

How Does an Economizer Work?

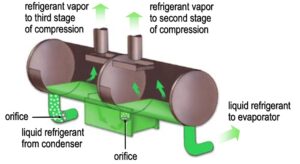

The economizer works by using a two-stage compression cycle:

1. Flash Gas Process – The liquid refrigerant passes through an expansion device, producing a mixture of vapor and liquid. The vapor (flash gas) is directed to an intermediate port of the compressor.

2. Pre-Cooling Effect – The remaining liquid refrigerant is further cooled, ensuring a lower temperature before entering the evaporator.

This process improves the refrigeration cycle’s thermodynamic efficiency, reducing overall power consumption.

Economizers in Industrial Chillers – Benefits

- Energy Savings – Lower compressor workload translates into reduced energy bills.

- Increased Cooling Capacity – Economizers enable chillers to provide additional cooling without extra energy input.

- Extended Equipment Life – Reducing compressor stress helps extend the lifespan of critical components.

- Sustainability Goals – By cutting energy use, economizers support environmental compliance and green certifications.

Applications of Economizers

Economizers are commonly used in: – Large industrial chillers in manufacturing plants. – HVAC systems in commercial complexes. – Data centers where reliable cooling and efficiency are critical. – Food and beverage industries for maintaining precise process temperatures.

Frequently Asked Questions (FAQs)

Q1: What is the main purpose of an economizer in a chiller?

An economizer improves energy efficiency by precooling refrigerant and reducing compressor workload.

Q2: How much energy can an economizer save?

Energy savings vary by system, but economizers can typically reduce chiller energy consumption by 10–20%.

Q3: Can economizers be retrofitted into existing chiller systems?

Yes, in many cases economizers can be added to existing systems, but feasibility depends on the chiller design.

Q4: Which industries benefit the most from economizers?

Industries with high cooling demands, such as data centers, manufacturing plants, and food processing, benefit significantly.

Q5: Does using an economizer extend equipment life?

Yes, by reducing compressor stress, economizers help prolong the lifespan of chillers and lower maintenance costs.

Conclusion

Economizers play a vital role in enhancing the efficiency of industrial chillers. By improving the thermodynamic performance of the refrigeration cycle, they not only save energy but also support sustainability initiatives. Other than investing in economizers, facilities can look into reduce operational costs and extend equipment lifespan through a complete industrial chiller optimization guide!